Description

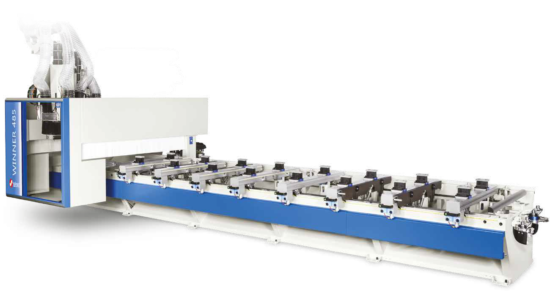

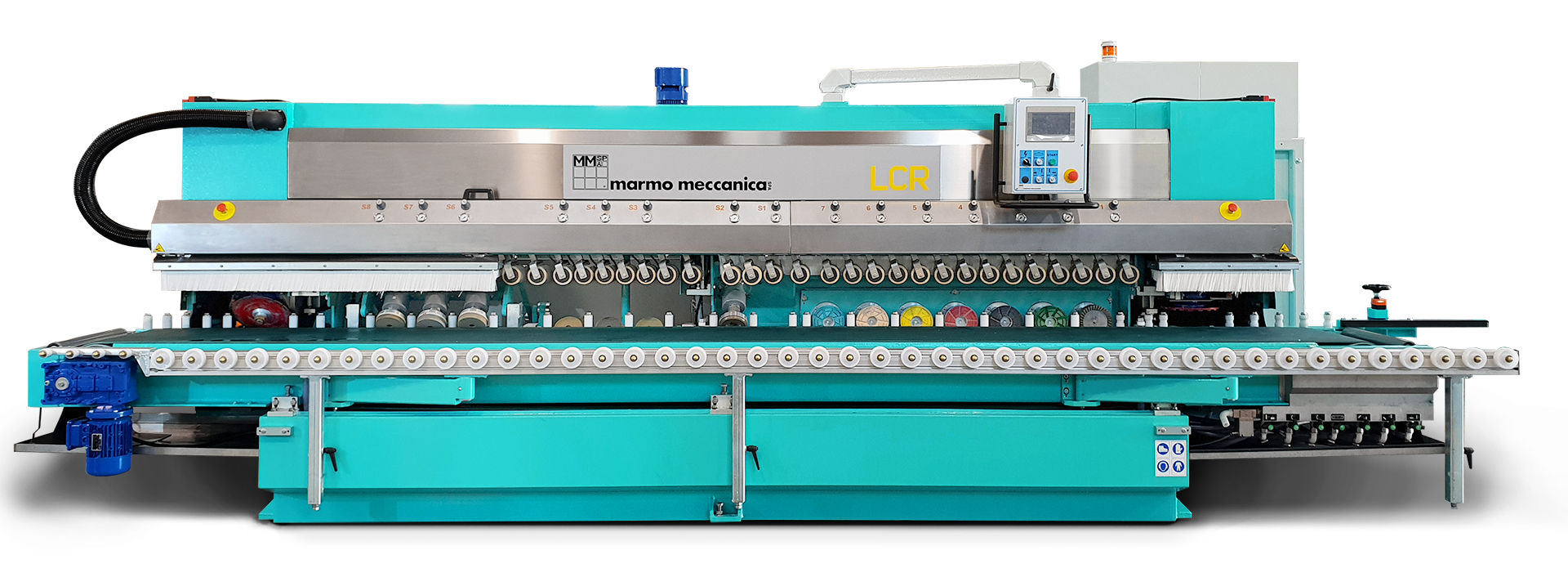

The LCR machine is supplied with two units of three counter-oscillating mandrels each, that can carry out spans of about 90° through an original and innovative mechanism invented by MM. That mechanism generates a natural, harmonious motion. It makes the masses of the two oscillating units balance out each other (and the reversing stresses compensate), thus allowing high oscillating frequencies. Alternatively, the two units of mandrels can be used in a static way (opposed at 45°), thus performing “classic” flat chamfering.

The LCR machine is supplied with two units of three counter-oscillating mandrels each, that can carry out spans of about 90° through an original and innovative mechanism invented by MM. That mechanism generates a natural, harmonious motion. It makes the masses of the two oscillating units balance out each other (and the reversing stresses compensate), thus allowing high oscillating frequencies. Alternatively, the two units of mandrels can be used in a static way (opposed at 45°), thus performing “classic” flat chamfering.

Briefly described, the LCR structure is composed of:

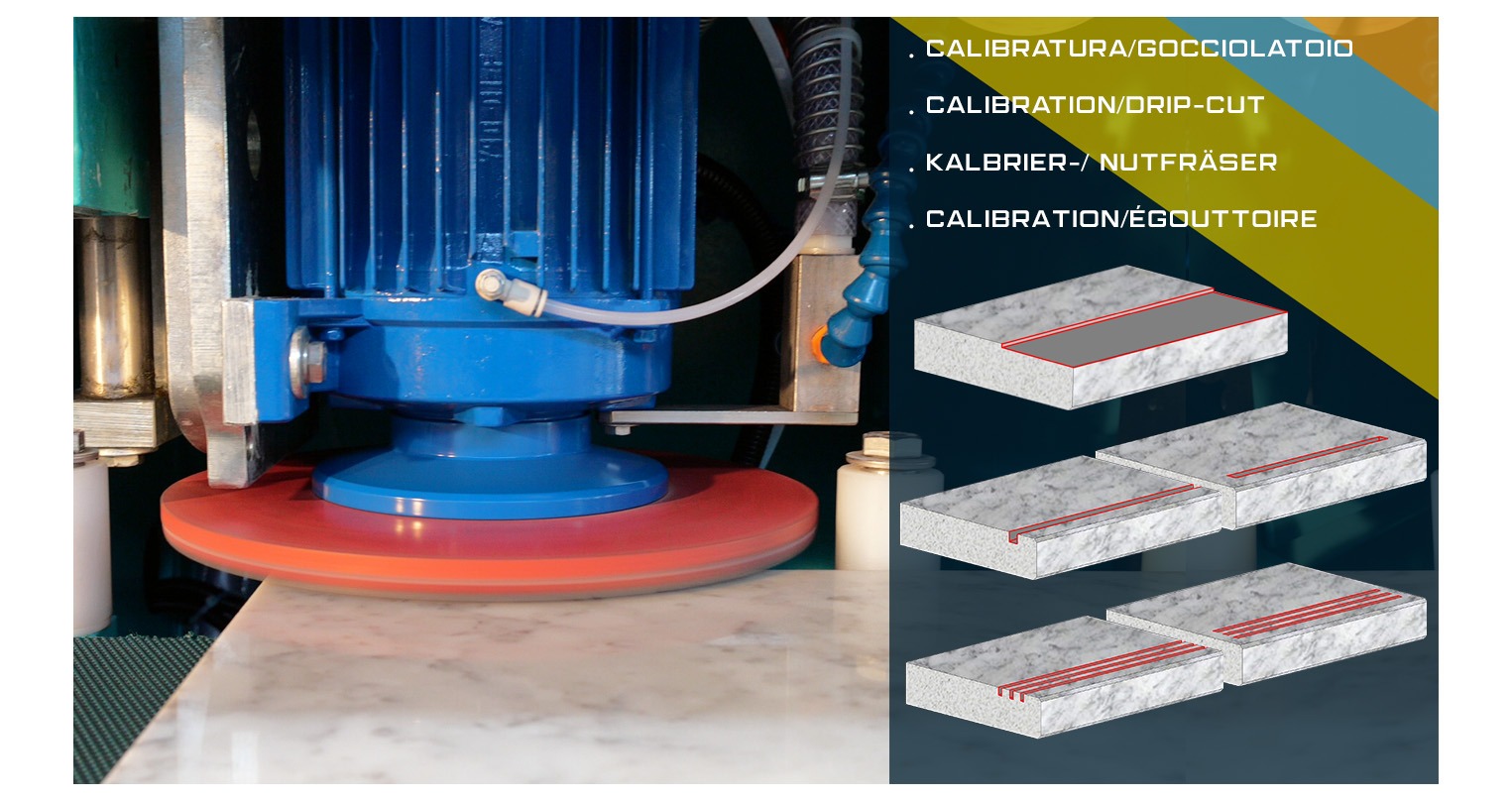

– no. 1 INGOING CALIBRATING/ DRIP-SIZING UNIT, both crosswise and lengthwise adjustable, to gauge the thickness of the material with a varying depth (max. 6 cm from the edge) or, rotated to the horizontal axis position, for dripstone cutting (6, 7 – A, D). – no. 7 MANDRELS FOR SMOOTHING AND POLISHING, the first of which equipped with a mechanical stop for diamond tool (4);

– no. 2 UPPER AND LOWER 45° CHAMFERING MANDRELS FOR PRECHAMFERING DIAMOND TOOLS, equipped with a mechanical stop, by which it is possible to establish the pencil-round edges dimensions (5, 8, 9);

– no. 2 GROUPS OF 3 MANDRELS EACH, COUNTER-OSCILLATING (mechanical stop on the 1st one of each group), for pencil-round chamfers (max. thickness 4 cm) (B) and 45° flat chamfers (max. thickness 6 cm) (C).